-

1 woollen loom

Текстиль: сукноткацкий станок -

2 woollen loom

English-Russian dictionary on textile and sewing industry > woollen loom

-

3 woollen and worsted loom

English-Russian dictionary on textile and sewing industry > woollen and worsted loom

-

4 сукноткацкий станок

Textile: cloth loom, felt loom, woollen loomУниверсальный русско-английский словарь > сукноткацкий станок

-

5 Skinner, Halcyon

[br]b. 6 March 1824 Mantua, Ohio, USAd. 28 November 1900 USA[br]American inventor of a machine for making Royal Axminster and other carpets.[br]Halcyon was the son of Joseph and Susan Skinner. When he was 8 years old, his parents moved to Stockbridge in Massachusetts, where he obtained education locally and worked on farms. In 1838 his father moved to West Farms, New York, where Halcyon helped his father make violins and guitars for seven years. He then worked as a general carpenter for eight years until he was hired in 1849 by Alexander Smith, a carpet manufacturer. Skinner designed and constructed a hand loom that could weave figured instead of striped carpets, and by 1851 Smith had one hundred of these at work. Skinner was retained by Smith for forty years as a mechanical expert and adviser.Weaving carpets by power started in the 1850s on enormous and complex machines. Axminster carpets had traditionally been produced in a similar way to those made by hand in Persia, with the tufts of woollen yarn being knotted around vertical warp threads. To mechanize this process proved very difficult, but Skinner patented a loom in 1856 to weave Axminster carpets although, it was not working successfully until 1860. Then in 1864 he developed a loom for weaving ingrain carpets, and c. 1870 he altered some imported English looms for weaving tapestry carpets to double their output.His most important invention was conceived in 1876 and patented on 16 January 1877. This was the Moquette or Royal Axminster loom, which marked yet another important step forward and enabled the use of an unlimited number of colours in carpet designs. This type of loom became known as the Spool Axminster because of the endless chain of spools carrying lengths of coloured yarns, wound in a predetermined order, from which short pieces could be cut and inserted as the tufts. It put Smith's company, Alexander Smith \& Sons, Yonkers, New York, in the lead among American carpet manufacturers. This type of loom was introduced to Britain in 1878 by Tomkinson \& Adam and spread rapidly. Skinner virtually retired in 1889 but continued to live in Yonkers.[br]Further ReadingBiography, American Machinist 23.Dictionary of American Biography, Vol. XVII.G.Robinson, 1966, Carpets, London (for the history and techniques of carpet weaving).A.Barlow, 1878, The History and Principles of Weaving by Hand and by Power, London (includes a section on pile weaving which covers some types of carpets).RLH -

6 Kay (of Bury), John

SUBJECT AREA: Textiles[br]b. 16 July 1704 Walmersley, near Bury, Lancashire, Englandd. 1779 France[br]English inventor of the flying shuttle.[br]John Kay was the youngest of five sons of a yeoman farmer of Walmersley, near Bury, Lancashire, who died before his birth. John was apprenticed to a reedmaker, and just before he was 21 he married a daughter of John Hall of Bury and carried on his trade in that town until 1733. It is possible that his first patent, taken out in 1730, was connected with this business because it was for an engine that made mohair thread for tailors and twisted and dressed thread; such thread could have been used to bind up the reeds used in looms. He also improved the reeds by making them from metal instead of cane strips so they lasted much longer and could be made to be much finer. His next patent in 1733, was a double one. One part of it was for a batting machine to remove dust from wool by beating it with sticks, but the patent is better known for its description of the flying shuttle. Kay placed boxes to receive the shuttle at either end of the reed or sley. Across the open top of these boxes was a metal rod along which a picking peg could slide and drive the shuttle out across the loom. The pegs at each end were connected by strings to a stick that was held in the right hand of the weaver and which jerked the shuttle out of the box. The shuttle had wheels to make it "fly" across the warp more easily, and ran on a shuttle race to support and guide it. Not only was weaving speeded up, but the weaver could produce broader cloth without any aid from a second person. This invention was later adapted for the power loom. Kay moved to Colchester and entered into partnership with a baymaker named Solomon Smith and a year later was joined by William Carter of Ballingdon, Essex. His shuttle was received with considerable hostility in both Lancashire and Essex, but it was probably more his charge of 15 shillings a year for its use that roused the antagonism. From 1737 he was much involved with lawsuits to try and protect his patent, particularly the part that specified the method of winding the thread onto a fixed bobbin in the shuttle. In 1738 Kay patented a windmill for working pumps and an improved chain pump, but neither of these seems to have been successful. In 1745, with Joseph Stell of Keighley, he patented a narrow fabric loom that could be worked by power; this type may have been employed by Gartside in Manchester soon afterwards. It was probably through failure to protect his patent rights that Kay moved to France, where he arrived penniless in 1747. He went to the Dutch firm of Daniel Scalongne, woollen manufacturers, in Abbeville. The company helped him to apply for a French patent for his shuttle, but Kay wanted the exorbitant sum of £10,000. There was much discussion and eventually Kay set up a workshop in Paris, where he received a pension of 2,500 livres. However, he was to face the same problems as in England with weavers copying his shuttle without permission. In 1754 he produced two machines for making card clothing: one pierced holes in the leather, while the other cut and sharpened the wires. These were later improved by his son, Robert Kay. Kay returned to England briefly, but was back in France in 1758. He was involved with machines to card both cotton and wool and tried again to obtain support from the French Government. He was still involved with developing textile machines in 1779, when he was 75, but he must have died soon afterwards. As an inventor Kay was a genius of the first rank, but he was vain, obstinate and suspicious and was destitute of business qualities.[br]Bibliography1730, British patent no. 515 (machine for making mohair thread). 1733, British patent no. 542 (batting machine and flying shuttle). 1738, British patent no. 561 (pump windmill and chain pump). 1745, with Joseph Stell, British patent no. 612 (power loom).Further ReadingB.Woodcroft, 1863, Brief Biographies of Inventors or Machines for the Manufacture of Textile Fabrics, London.J.Lord, 1903, Memoir of John Kay, (a more accurate account).Descriptions of his inventions may be found in A.Barlow, 1878, The History and Principles of Weaving by Hand and by Power, London; R.L. Hills, 1970, Power in theIndustrial Revolution, Manchester; and C.Singer (ed.), 1957, A History ofTechnology, Vol. III, Oxford: Clarendon Press. The most important record, however, is in A.P.Wadsworth and J. de L. Mann, 1931, The Cotton Trade and IndustrialLancashire, Manchester.RLH -

7 Serge

SARGE, SERGEA coarse, woollen cloth known as early as the 12th century, a finer quality being called " say." It was much used during the Middle Ages for all portions of attire by the poorer classes, and in the piece for the decoration of houses. ————————SERGE (U.S.A.)The specification issued by the U.S.A. Government is as follows: - Cotton and worsted serge for overcoat lining shall be of single or 2-ply cotton warp and single or 2-ply worsted filling, the wool to be not below 46's grade; the width shall be full 36-in. exclusive of the selvedge and shall weigh from 6-oz. to 7-oz. per linear yard; it shall be woven in regular serge weave and constructed so as to give a fabric with good body and twill line on the face and containing approximately equal quantities of worsted and cotton yarns throughout; to be navy-blue, fast to the light, with both sets of threads and to be put up into bookfold. ———————— This term was formerly applied in Yorkshire to rough handling coarse wool fabrics woven in a twill design. An old 6-end serge was a simple diagonal 3 up, 1 down, 1 up, 1 down. The term serge is now almost universally understood to mean the 2 & 2 twill, and sometimes the 3 & 3 and the 4 & 4 twills. In wool fabrics it is the practice to add to the name serge, the definition of botany to distinguish fine wool serges from cross-bred qualities. A typical botany worsted serge, 2 & 2 twill weave, 21-02. per yard, 56/58-in. is made with 2/20's worsted 64/70's quality, S twist, 46 ends and 46 picks per inch, 72-in. wide in loom, woven white arid piece-dyed. The cloth is clear finished so as to obtain a well-defined twill effect. A usual weight for ladies' costume serge is 12/13-oz. per yard. Serges are made in many qualities ranging from 12-oz. to 26-oz. per yard. Crossbred worsted yarns are used in making the rougher and stronger types, while woollen yarns are also used. A serge which is extensively used in uniforms for transport workers is made with two-fold cross-bred worsted yarn for warp and single Cheviot woollen yarn for weft. The cloth is woven white or grey and piece-dyed. -

8 Broadcloth

Given to an all-cotton cloth used for many dress purposes, bleached, dyed and printed 35-in./90 yards 124 X 64 per inch, 36's/40's yarns, 22-lb. plain weave. Better qualities have two-fold warp or two-fold warp and weft, generally 2/80's Egyptian, which greatly resemble Lancashire poplins. ———————— A term that in many districts was used to indicate garments worn by the clergy. It is a stout wool cloth. Made from fine merino yarns, and heavily milled and - finished with a dress face. It has a velvety feel and a silky gloss. A 90-in. in the loom gives 56-in. finished. One quality is made 32 X 40 per inch, from 26 skeins warp and weft. Dyed black or indigo. Another type is made from West of England woollen yams in very wide widths, and shrunk during finish about 33 per cent. Woven 2 X 1 twill. Quality varies according to price. It is a superfine, smooth-faced and dense fabric, and considered the perfection in woollen materials. -

9 Naps

An all-wool overcoating made 72-in. wide in the loom to finish 58-in. Woven with indigo dyed yarns about 36 ends and 48 picks per inch. Good quality felting yarns are used and when finished the weave is not visible. During finishing the surface of the cloth is rubbed into small knots. Naps are very similar to Witneys, Waverleys, etc. Typical cloths are made as follow: - Union Nap - Warp 2/40's cotton, 60 ends and 48 picks per inch. Face weft 110 yards per oz. openband mungo, back weft 54 yards per oz. openband shoddy, weight 26-oz. per yard. All Wool - Warp 250 yards per oz. cross-band woollen weft 310 yards per oz. openband woollen, 56 ends and 104 picks per inch. R gives the weave for Reversible Witney, N for Nap and Sardinian, and W for Waverley. NAP WARP - An old time name for pile warp.

-

10 tejer

v.1 to weave (hilos, mimbre).2 to knit (hacer punto).3 to spin (telaraña).4 to carve out (labrar) (porvenir).5 to tell, to invent, to spin.* * *1 (en telar) to weave2 (hacer punto) to knit3 (araña) to spin\tejer y destejer figurado to chop and change* * *verb1) to knit2) weave* * *1. VT1) [+ tela] to weave; [+ tela de araña] to spin, make; [+ capullo] to spin2) (=hacer punto) to knit; (=hacer ganchillo) to crochet; (=coser) to sew3) [+ complot] to hatch; [+ plan] to devise; [+ mentira] to fabricate; [+ cambio etc] to bring about little by little2. VI1) [en telar] to weave2) (=hacer punto) to knit; (=hacer ganchillo) to crochet; (=coser) to sew* * *1.verbo transitivo1)a) ( en telar) to weaveb) (con agujas, a máquina) to knit; ( con ganchillo) to crochetc) araña to spin2.tejer vi ( en telar) to weave; (con agujas, a máquina) to knit; ( con ganchillo) to crochet* * *= spin, weave.Ex. Then the fairies told them how happily the spiders lived among the green leaves spinning garments for their neigbbors.Ex. This article compares an expert system to a rug and the shell to the loom on which it was woven.----* aguja de tejer = knitting needle.* arte de tejer = weaving.* máquina de tejer = knitting machine.* tejer una historia = weave + story.* tejer una telaraña = draw + web.* * *1.verbo transitivo1)a) ( en telar) to weaveb) (con agujas, a máquina) to knit; ( con ganchillo) to crochetc) araña to spin2.tejer vi ( en telar) to weave; (con agujas, a máquina) to knit; ( con ganchillo) to crochet* * *= spin, weave.Ex: Then the fairies told them how happily the spiders lived among the green leaves spinning garments for their neigbbors.

Ex: This article compares an expert system to a rug and the shell to the loom on which it was woven.* aguja de tejer = knitting needle.* arte de tejer = weaving.* máquina de tejer = knitting machine.* tejer una historia = weave + story.* tejer una telaraña = draw + web.* * *tejer [E1 ]vtA1 (en un telar) to weavealfombras tejidas a mano hand-woven rugs2 (con agujas, a máquina) to knit; (con ganchillo) to crochetmáquina de tejer knitting machine3 «araña» to spinB(elaborar, desarrollar): tejieron un plan para asesinarlo they devised a plan o they plotted to murder himtejió una intriga vergonzosa he wove a shameful web of intriguetejió una gran mentira she spun an elaborate lie■ tejervi1 (en un telar) to weave2 (con agujas, a máquina) to knit3 (con ganchillo) to crochet* * *

tejer ( conjugate tejer) verbo transitivo

( con ganchillo) to crochet;

verbo intransitivo ( en telar) to weave;

(con agujas, a máquina) to knit;

( con ganchillo) to crochet

tejer verbo transitivo

1 (en el telar) to weave: la araña tejía su red, the spider wove its web

2 (calcetar) to knit: me tejió un jersey, he knitted me a pullover

3 fig (una fantasía, historia) to weave

(maquinar, urdir) to plot, scheme

' tejer' also found in these entries:

Spanish:

hilo

- aguja

- menguar

- palillo

English:

knit

- spin

- weave

- crochet

- knitting

- needle

- purl

* * *♦ vt1. [hilos, mimbre] to weave;tejió una cesta de mimbre she made a wicker basket;artículos tejidos a mano hand-woven goods2. [labor de punto] to knit;tejer algo a ganchillo to crochet sth3. [telaraña, capullo] to spin4. [labrar] [porvenir] to carve out;[ruina] to bring about♦ vi1. [hacer punto] to knit;tejer a ganchillo to crochet;tejer y destejer to change (opinions/behaviour), Br to chop and change2. [araña, gusano] to spin* * *intriga deviseII v/i L.Am.plot, scheme* * *tejer vt1) : to knit, to crochet2) : to weave3) fabricar: to concoct, to make up, to fabricate* * *tejer vb -

11 Algerienne

A heavy material used for curtains, awnings and tents in North Africa. Made from coarse woollen yarns, with coloured cross-over bars in the weft. A check-loom fabric. -

12 Automobile Cloaking

Very heavy woollen double cloth, used in America for motor car coats, blankets and wraps. The fabric is simply two cloths in twill weaves, stitched together in the loom by a cotton warp. The face cloth may differ in colour from the back. Usually China wool is used as the large amount of kemp it contains, gives an appearance to the cloth not obtainable any other way. Woven about 30 ends, 34 picks per inch, 68-in. wide, weighing 34-oz. per yard. Warp yarns are coarse-grade wool, weft yarns usually coarse shoddy. The cotton binding warp is about 2 / 16's and only 2-to 3-ends per inch, so that the two cloths can be separated, if desired. Each cloth is 15 X 17 per inch.Dictionary of the English textile terms > Automobile Cloaking

-

13 Covert Cloth

A woollen cloth made with two-fold warp and single weft, very closely woven. It is a fine warp twill weave, and the weft does not show on the face. Venetian coverts have a rib twill weave. For medium weight suitings and light overcoats, the warp is a two-fold marl yarn, and woven with the seven-shaft warp twill. The cloth is made 72-in. loom width to finish 58-in., 64 ends 60 picks per inch, 2/50's T., 22's W., all West of England yarns. A mottled appearance is a characteristic of this coating and is produced by the use of grandrelle yarns. -

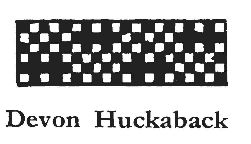

14 Devon

DEVON, or MEDICAL HUCKThis is the simplest form of huckaback weave, and is on 10 ends and 6 picks. The warp threads are usually dented three and two per dent alternately, which tends to prevent the threads splitting in the cloth and forming cracks. Woven with two picks in a shed. Woven about 58 ends and 30 double picks per inch, from 30's and 26's linen yarns, 25-in. wide cloth. Another cloth is made 26-in. wide, reed 30 porter (two and three threads alternately), reed width 281/2-in., warp 3-lb. flax (331/3 per cent loss), weft 4-lb. flax (331/3 per cent loss), 24 double shots on 37/40-in. glass, laid 111 yards, loom length 95 yards, finished length, 102 yards. These details are as usually used in the trade ————————

A heavy felted woollen overcoating cloth.

————————

A heavy felted woollen overcoating cloth. -

15 Hairline Tri-Colour

An imitation hairline fabric, woven from woollen warp and worsted weft. If red, blue and white are used for warp then the weft is similarly dyed. In the weave shown, are two ends of each colour together and the ends are all lifted except those of the same colour as the pick about to be thrown across. This gives a three-colour stripe with each colour well defined. The rib weave used also gives a balanced cloth. One quality is made 72-in. wide in the loom, 26 ends of 3 run wool warp and 60 picks of 2/30's worsted weft per inch. The weight is about 14-oz. per yard.

Dictionary of the English textile terms > Hairline Tri-Colour

-

16 Imitation Homespun

Woollen fabric made to imitate cloth which is hand-woven from hand-spun yarn. A medium grade of wool is used, fairly long staple, and free from all foreign matter. Woven 2 & 2 twill, 32 ends and 40 picks per inch; weighing about 11-oz. per yard for 68-in. loom state. Cloths up to 15-oz. or 16-oz. are also made. Yarns for 11-oz. cloth are 5 run (American)Dictionary of the English textile terms > Imitation Homespun

-

17 Llama Coating

An overcoating cloth made with llama wool face. It is finished with a long nap which is rippled on a special machine. One quality is made 72-in. (loom) 52 ends and 70 picks per inch, warp 4 run, face weft 21/2 run and back weft 4 run woollen yarns. Usually the yarns are dyed browns, red and greens. The back weft is generally shoddy. In the weave given strokes represent face weft and full squares back weft on 8 shafts. This cloth very often has a velour finished back.

-

18 Looker-Over

LOOKER-OVER, PERCHER, or PASSEROperatives in woollen and worsted mills who examine the woven pieces after leaving the loom and mark with chalk all faults which can be repaired during the subsequent processes of picking, hurling and mending. When dyed and finished the pieces are again examined (see Perching) -

19 Percher

LOOKER-OVER, PERCHER, or PASSEROperatives in woollen and worsted mills who examine the woven pieces after leaving the loom and mark with chalk all faults which can be repaired during the subsequent processes of picking, hurling and mending. When dyed and finished the pieces are again examined (see Perching) -

20 Passer

LOOKER-OVER, PERCHER, or PASSEROperatives in woollen and worsted mills who examine the woven pieces after leaving the loom and mark with chalk all faults which can be repaired during the subsequent processes of picking, hurling and mending. When dyed and finished the pieces are again examined (see Perching)

- 1

- 2

См. также в других словарях:

textile — /teks tuyl, til/, n. 1. any cloth or goods produced by weaving, knitting, or felting. 2. a material, as a fiber or yarn, used in or suitable for weaving: Glass can be used as a textile. adj. 3. woven or capable of being woven: textile fabrics. 4 … Universalium

Glossary of textile manufacturing — For terms specifically related to sewing, see Glossary of sewing terms. For terms specifically related to dyeing, see Glossary of dyeing terms. The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first… … Wikipedia

Textile manufacturing terminology — The manufacture of textiles is one of the oldest of human technologies. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. (Both fibre and fiber are used in this article.)… … Wikipedia

Spinning mule — A pair of Condenser spinning mules. These have 741 spindles, being cut down from 133 feet (41 m) 1122 spindles they used to have up until the 24th Sept 1974, when they were retired from Elk Mill, Royton. The mule was built by Platt Brothers … Wikipedia

tapestry — tapestrylike, adj. /tap euh stree/, n., pl. tapestries, v., tapestried, tapestrying. n. 1. a fabric consisting of a warp upon which colored threads are woven by hand to produce a design, often pictorial, used for wall hangings, furniture… … Universalium

Shaw and Crompton — Coordinates: 53°34′37″N 2°05′31″W / 53.577°N 2.092°W / 53.577; 2.092 … Wikipedia

History of clothing and textiles — Ladies making silk, early 12th century painting by Emperor Huizong of Song (a remake of an 8th century original by artist Zhang Xuan), illustrates silk fabric manufacture in China. The wearing of clothing is exclusively a human characteristic and … Wikipedia

Weaving — Weaver (occupation) redirects here. This article is about textile weaving. For other uses, see Weaving (disambiguation). Warp and weft in plain weaving Weaving is a method of fabric production in which two distinct sets of yarns or threads are… … Wikipedia

floor covering — Finish material on floors, including wood strips, parquet, linoleum, vinyl, asphalt tile, rubber, cork, epoxy resins, ceramic tile, and carpeting. Wood strip flooring, attached to a subfloor of plywood, is most popular, especially for residences … Universalium

Wool — is the fiber derived from the specialized skin cells, called follicles, [Australian Wool Corporation, Australian Wool Classing, Raw Wool Services, 1990] of animals in the Caprinae family, principally sheep, but the hair of certain species of… … Wikipedia

Cotton mill — A cotton mill is a factory that houses spinning and weaving machinery. Typically built between 1775 and 1930, mills spun cotton which was an important product during the Industrial Revolution. Cotton mills, and the mechanisation of the spinning… … Wikipedia